The application of reactive polyurethane hot melt adhesives in automotive interiors not only has good environmental performance, but also has the characteristics of strong adhesion, good thermal stability, and strong oxidation resistance, which is very in line with the requirements of the automotive industry for cost and high quality standards . Reactive polyurethane hot melt adhesives are used in automotive interiors by most automotive companies.

1.Product Introduction of the Automotive interior reactive hot melt adhesive

1. It has the characteristics of strong adhesion, high & low temperature resistance, water vapor resistance and strong oxidation resistance

2. Excellent initial strength, cross-linking and curing function, higher final bonding strength.

3. No organic solvent, 100% solid content, green and environmental protection.

2.Product Parameter (Specification) of the Automotive interior reactive hot melt adhesive

|

Color

|

Opening Hours

|

Viscosity

|

Operating temperature

|

|

Pure White & Natural Color

|

2-3min

|

25000-30000 CPS(140℃)

|

120-140℃

|

3.Product Feature And Application of the Automotive interior reactive hot melt adhesive

Reactive polyurethane hot melt adhesive for automotive interiors has the characteristics of strong adhesion, high & low temperature resistance, corrosion resistance, methanol resistance, water vapor resistance, and oxidation resistance. Reactive polyurethane hot-melt adhesives can be seen in the composite of car roof fabrics, car floor mat assemblies, trunk mat assemblies, damping panels, seats, etc.

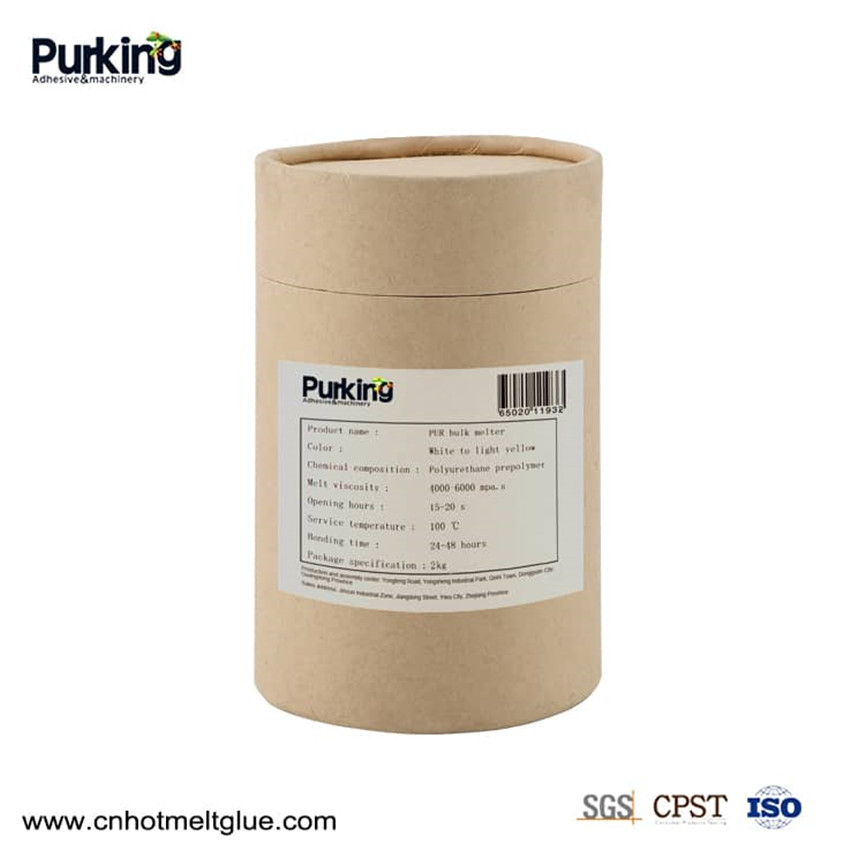

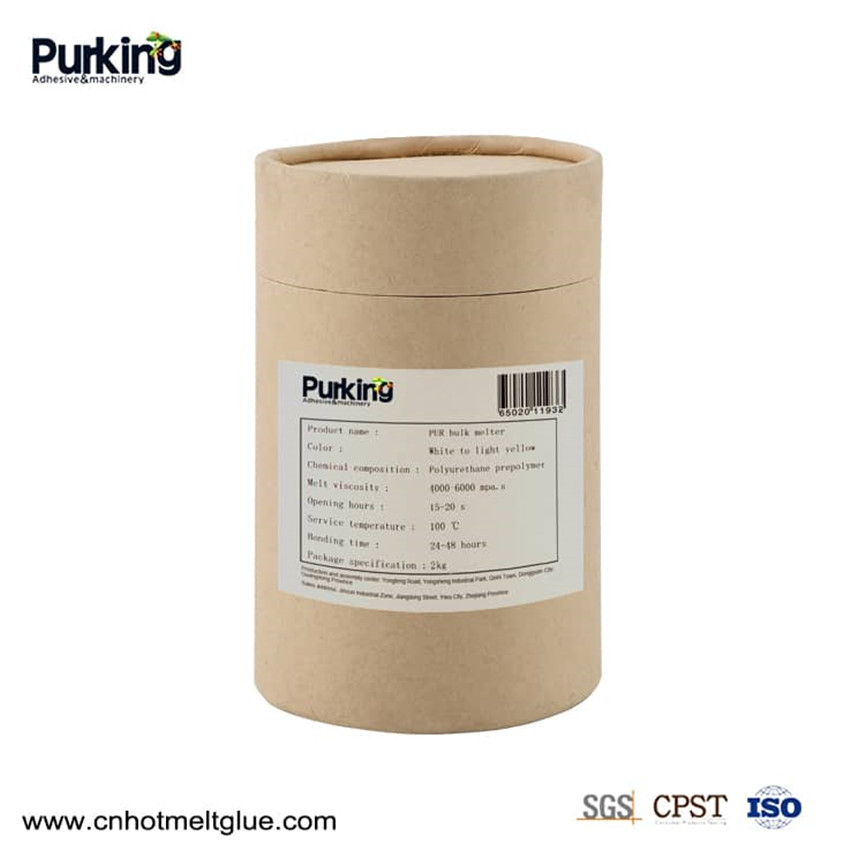

4.Product Details of the Automotive interior reactive hot melt adhesive

5.Product Qualification of the Automotive interior reactive hot melt adhesive

6.Deliver,Shipping And Serving of

the Automotive interior reactive hot melt

adhesive

The payment method is paypal, credit card, etc., and the transportation method is FOB. We will provide you with 7*24 hours tracking service and technical support, so that you can worry-free after sales.

7.FAQ

1. Q: Is the reactive polyurethane hot melt adhesive toxic during use?

A: Reactive polyurethane hot melt adhesive is an environmentally friendly solid adhesive that melts at high temperature and has the characteristics of high strength, fast bonding, and non-toxic. Therefore, the hot melt adhesive is non-toxic during use and can be used with confidence.

2. Q: What are the differences and advantages between reactive polyurethane hot melt adhesives and hot melt adhesives?

A: The main difference lies in the equipment used, storage environment and bonding method. Reactive hot melt adhesives will react with moisture in the air and must be isolated from the air and sealed for storage. The bonding process is a chemical reaction, so the bonding strength is high and it is widely used in various fields.

3. Q: How long is the shelf life of your hot melt adhesive?

A: Can be placed for 2 years at room temperature without deterioration.

4. Q: What

certifications have your hot melt adhesives passed?

A: Our hot melt adhesive

has passed SGS and ROHS testing.

5. Q: What are the characteristics of reactive polyurethane hot melt adhesive?

A: Reactive polyurethane hot melt adhesives will react with moisture in the air and must be isolated from the air. The bonding process is a chemical reaction, with high bonding strength, high temperature and low temperature resistance.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик