During the use of polyurethane hot melt adhesive, it needs to be heated and melted, and kept in a molten state for extrusion. Therefore, under the action of long-term heat and oxygen, the polymer chains of its main components such as matrix polymer, tackifier, wax, etc., the carbon-hydrogen bond is easily broken, and a chain oxidation reaction occurs, causing the relative molecular weight to decrease, making the adhesive Viscosity and color change, affecting the use of glue. The glue should maintain viscosity stability during use, so as to keep the glue extrusion and coating amount uniform, and keep the color unchanged. The chain process of oxidation greatly reduces the heat aging speed, prevents the deterioration of the glue and the reduction of the bonding strength, etc.

What are the requirements for antioxidants used as adhesives:

The following requirements should be met:

1. Good compatibility with adhesives, preferably compatibility;

2. Good inhibition and anti-oxidation performance;

3. Does not affect the process and physical and mechanical properties of the adhesive;

4. Stable storage, no discoloration, delamination, gelation, deterioration, etc. of the adhesive;

5. Non-toxic or low toxicity, less polluting;

6. The source is easy and the price is reasonable.

What are the commonly used antioxidants for polyurethane hot melt adhesives? There are mainly two types;

One is a chain transfer agent, which forms a stable free radical by itself while giving an active hydrogen atom, such as N-phenyl-β-naphthylamine;

Features of N-phenyl-β-captylamine: light gray powder, gradually turning gray-red when exposed to air or sunlight, relative density 1.20, melting point 108°C, insoluble in water, flammable, highly toxic, regarded as Carcinogens; should be used as little or as little as possible. It can be replaced by its N, N, N', N'-tetraphenylaminomethane, its characteristics: off-white powder or amber liquid, melting point range 29-36 ° C, three-dimensional structure content ≥ 35%, this antioxidant effect High, low pollution and coloring. Compared with other amine antioxidants, its outstanding advantages are small migration, low pollution, slight toxicity, good heat resistance and oxidation resistance, and can completely replace N-phenyl-β-naphthylamine, And better performance.

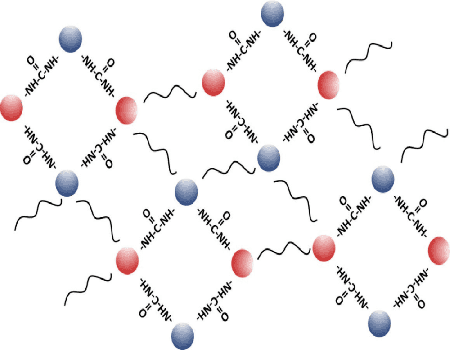

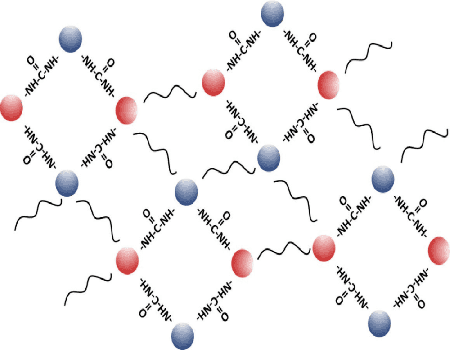

The other is sterically hindered phenols, which are characterized by one or two larger tert-butyl groups at the ortho position of the Phenolic hydroxyl group, using steric hindrance and a higher conjugation system to make the phenols generated after chain transfer Free radical stabilization, such as 2,6-di-tert-p-cresol. Usually the amount of antioxidants is 0.1% to 1.5%, generally not more than 2%. Antioxidants are mainly phenols and phenol derivatives.

2,6-Di-tert-butyl-p-cresol: The pure product is white crystal, the color turns yellow when exposed to light, and gradually deepens, the relative density is 0.8937, and the melting point is 70°C. Soluble in dry benzene, toluene, methanol, ethanol, isopropanol, butanone, carbon tetrachloride, petroleum ether, insoluble in dry water and dilute alkali solution, flammable, non-toxic, used as a non-polluting antioxidant, effective Inhibit air oxidation, thermal degradation and copper damage, and have a protective effect on thermal aging. 4,4'-Thiobis(3-methyl-6-tert-butyl)phenol, white or light yellow powder, relative density 1.06-1.12, melting point 161-164°C. Soluble in ethanol, ether, acetone, benzene, slightly soluble in petroleum ether, gasoline, insoluble in water. Low toxicity, as a non-polluting antioxidant, low volatility, high-efficiency anti-oxidation, excellent thermal stability and weather resistance.

The antioxidant used in a good hot melt adhesive is a highly efficient antioxidant with excellent thermal stability and weather resistance. It has the characteristics of insoluble in water, low toxicity, good heat resistance & oxygen resistance.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик