What is PUR hot melt adhesive?

1 concept

PUR (Polyurethane Reactive), the Chinese full name is moisture curing reactive polyurethane hot melt adhesive. The main component is isocyanate-terminated polyurethane prepolymer. The adhesion and toughness (elasticity) of PUR can be adjusted, and it has excellent bonding strength, temperature resistance, chemical corrosion resistance and aging resistance. In recent years, it has become one of the important varieties in the adhesive industry. Now it is widely used in packaging, wood processing, automobile, textile, electromechanical, aerospace and other national economic fields.

2 Properties of polyurethane hot melt adhesive

The reactive hot melt adhesive is heated and melted into a fluid under the condition of inhibiting the chemical reaction, so as to facilitate coating; after the two adherends are bonded and cooled, the adhesive layer condenses to play a bonding role; and then with the help of moisture in the air It reacts with the moisture attached to the surface of the adherend, extends the chain, and generates a high-molecular polymer with high cohesion, which significantly improves the adhesion, heat resistance, and low temperature resistance. Due to its extremely high reactivity, it shows excellent adhesion to various materials, and is widely used in washing machine top covers, disinfection cabinet top covers, book binding, car lights, furniture edge banding, shoemaking etc. bonding.

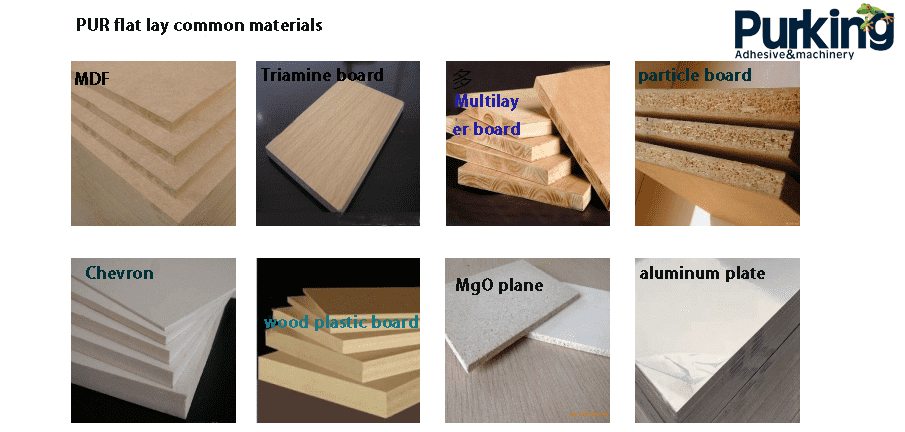

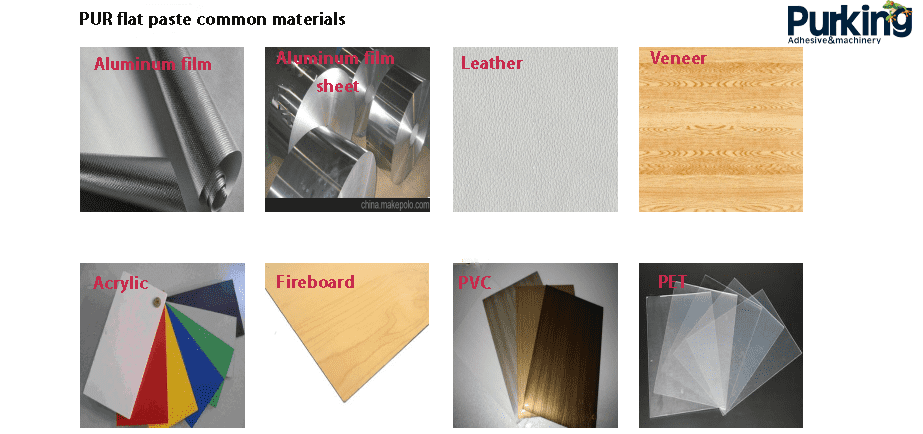

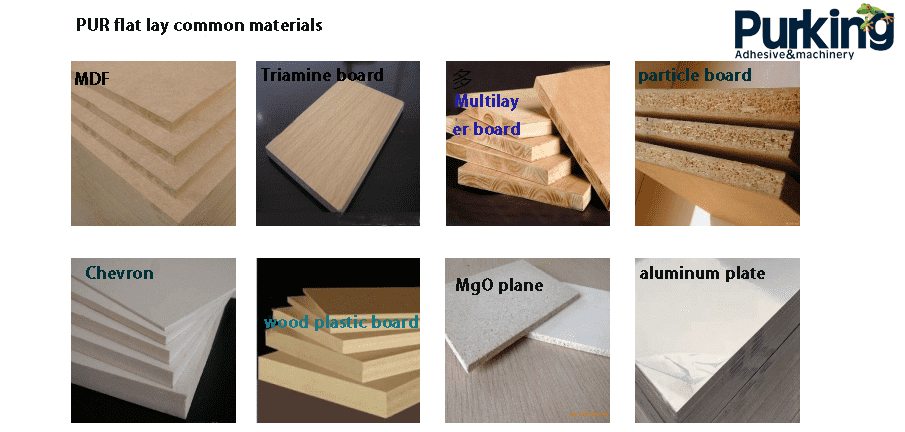

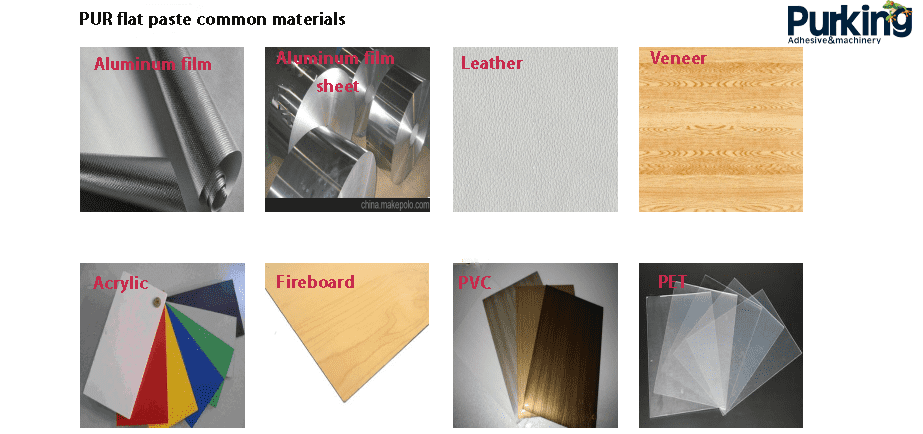

PUR adhesive is a polar and chemically active urethane group (-NHCOO-) or isocyanate group (-NCO) in its molecular structure, and it can be used with materials containing active hydrogen, such as porous materials such as wood, leather, fabric, paper, ceramics, etc. It has excellent adhesion to plastic, metal, glass, rubber and other smooth surface materials.

3 Types of Polyurethane Hot Melt Adhesives

According to chemical properties, polyurethane hot melt adhesives can be divided into two categories, one is thermoplastic polyurethane hot melt adhesives, and the other is reactive polyurethane hot melt adhesives. The former is liquefied by heating and then solidified by cooling, while the latter is liquefied by heating and then cross-linked and solidified by cooling and moisture reaction. Thermoplastic polyurethane hot melt adhesive is also called hot melt polyurethane hot melt adhesive (TPU). The reactive polyurethane hot melt adhesive (PUR) can be divided into moisture curing polyurethane hot melt adhesive and closed polyurethane hot melt adhesive.

Polyurethane hot melt adhesives also have other classification criteria, such as according to shape, can be divided into three types: film, tape and powder. After the solution volatilizes on the surface of the material to be bonded, it becomes a hot melt adhesive film. Tapes are backed with a reinforcement or carrier, while films are supported by the adhesive itself.

Dear Sir/Madam

Thank you for being able to see the end. In our Purking company, there is a laboratory specializing in customized services. You can also choose the hot melt adhesive you need above our products, and we will reply you as quickly as possible.

best regards

jerry

Manager

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик