1.Advantages of PUR products: high efficiency, energy saving, environmental protection

Due to the outstanding physical and chemical properties of polyurethane and a wide range of applicability, it will replace traditional adhesives to a certain extent, such as most industrial solvent-based adhesives, part of the EVA hot melt adhesive, part of the VAE water-based adhesives, part of the tri-formaldehyde adhesive, part of the water-based polyurethane adhesive PUD, 2K PU, etc..

Because PUR products can be efficient, energy saving and environmental friendly. In the flat paste market, PUR has a unique advantage over water glue, and in the edge sealing market, PUR can provide high quality furniture products, which is beyond the reach of EVA and will develop rapidly.

2.PUR wrapping, PUR flat paste, PUR sealing application introduction

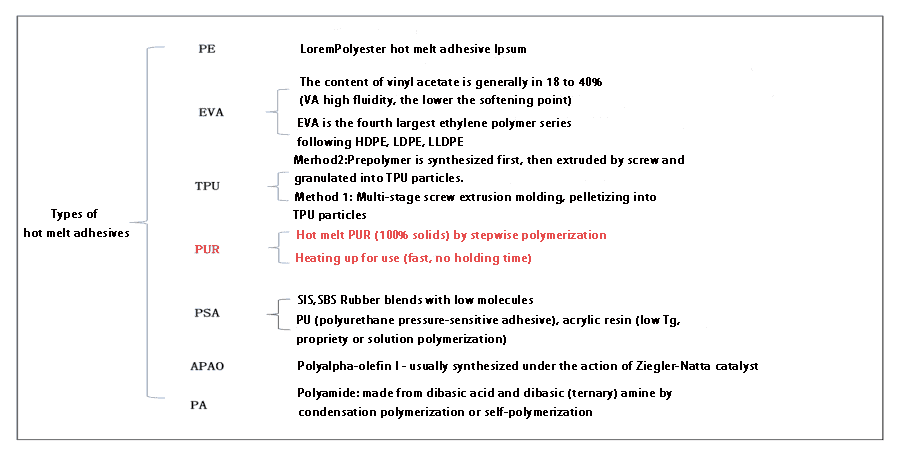

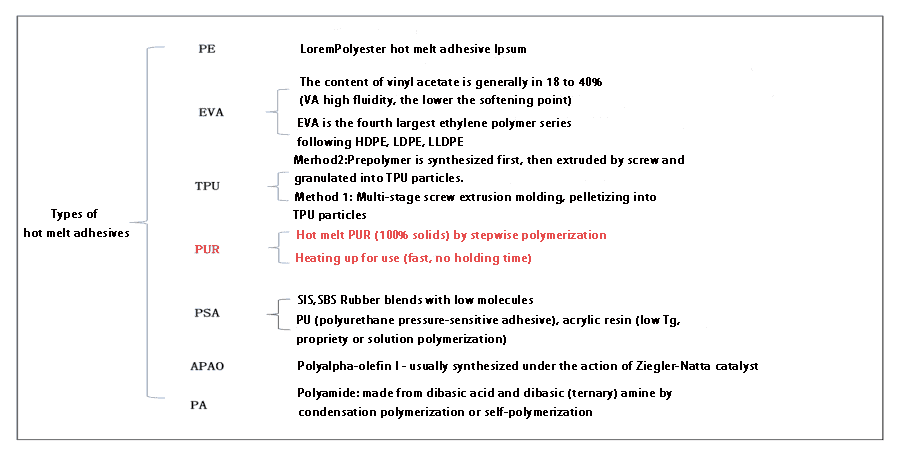

What are the essential differences between PUR adhesives and ordinary hot melt adhesives? The difference mainly lies in the fact that ordinary hot melt adhesive will fall off when heated, but PUR will not. PUR polyurethane adhesive curing process requires two necessary conditions, namely humidity and temperature, the higher the temperature, the faster the curing; the higher the humidity, the faster the curing.

At present, the application of PUR in the international woodworking and furniture field includes three aspects: PUR wrapping, PUR flat paste, PUR sealing, among which, the application of PUR wrapping has been very mature.

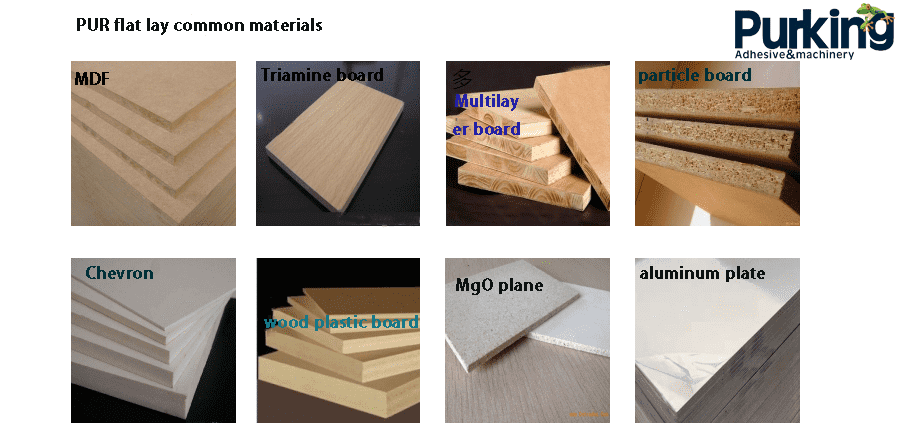

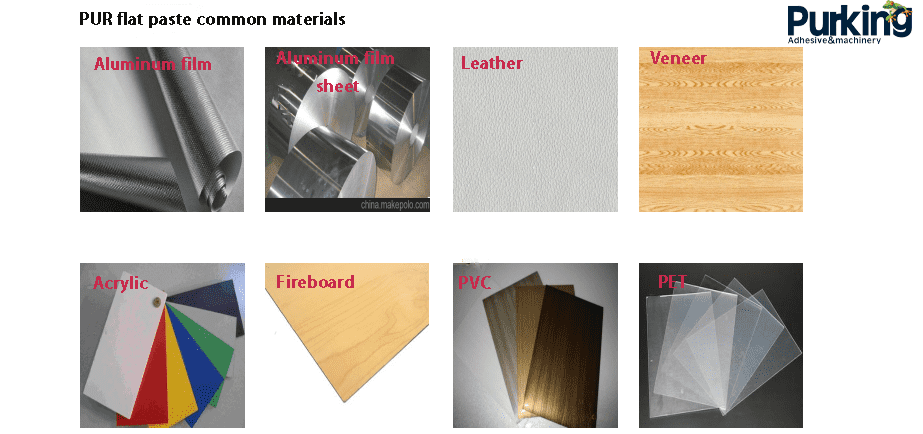

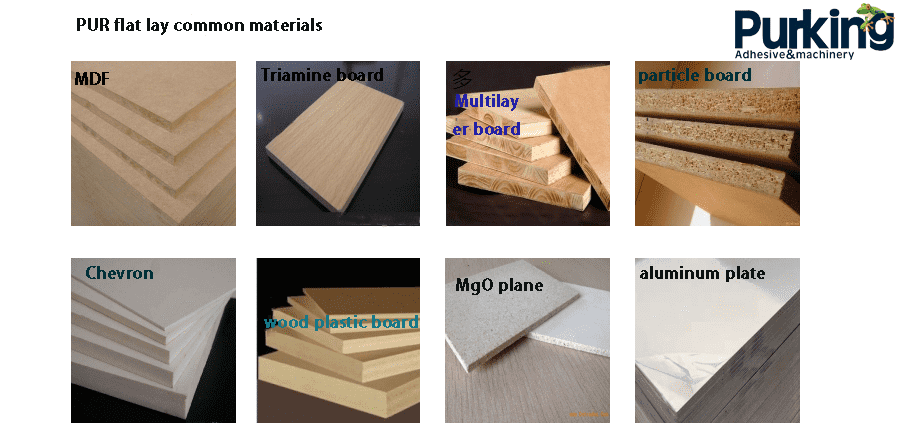

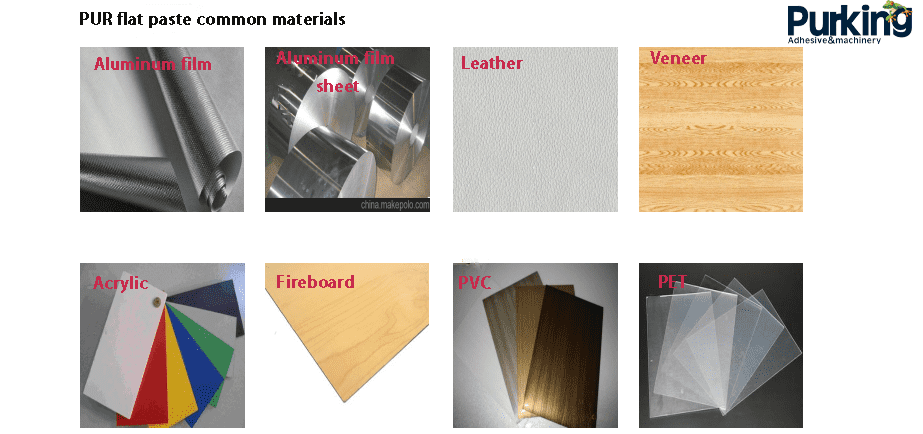

PUR flat paste application is emerging on a large scale, flat paste application is emerging on a large scale reflected in these aspects. The upgrade of the end consumer: consumers turn more to light luxury clean and simple, personalized custom style; flat paste material complexity: flat paste material diversification, diversification of the combination of substrates lead to flat paste material complexity; consumer requirements for aesthetics, environmental protection is higher, the requirements of the adhesive is also very high, the need for adaptability, environmental protection.

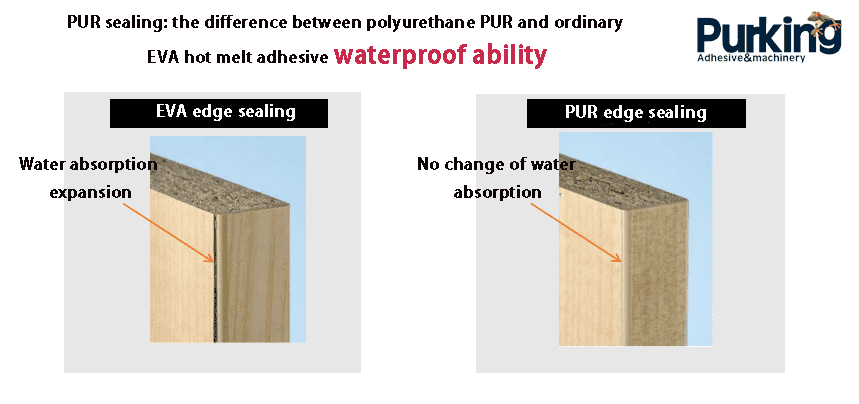

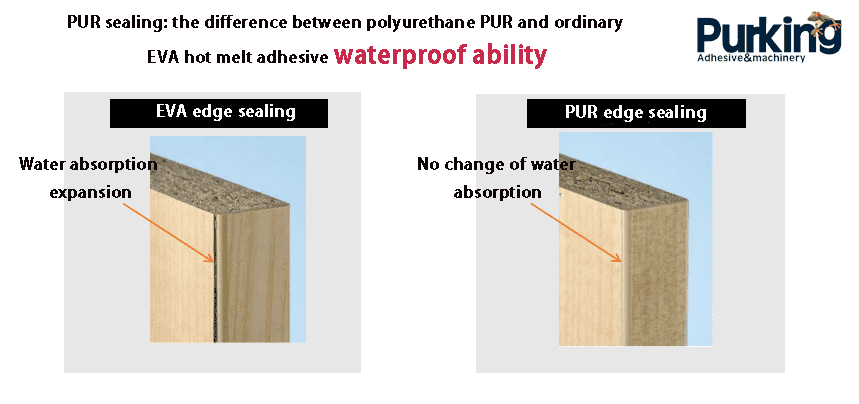

PUR sealing in polyurethane PUR and ordinary hot melt adhesive performance comparison, PUR in bonding, cold resistance, heat resistance, solvent resistance, aging resistance and other aspects of obvious advantages.

Due to the special nature of PUR's sealing, it needs regular cleaning of the equipment, and the cost is slightly higher than EVA. However, good process and good products need the joint efforts of customers, equipment manufacturers and material suppliers.

PUR flat lamination substrate combination is very complex, the PUR adhesive adaptability requirements are very high, the requirements of the adhesive requirements such as transparent, which is much more complicated than the overlay, but Purking has been focusing on the research of PUR flat lamination adhesive, and is committed to meet the diversified needs of customers.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик