5 gallons of moisture curing reactive polyurethane hot melt adhesive is also polyurethane pur hot melt adhesive glue, which is only packaged differently. Its working principle is that the polyurethane prepolymer reacts with the moisture in the air, solidifies and cross-links to form a stable chemical structure. Easy glue application, low melting point, glue can be applied at 110°C. Widely used in edge banding of edge banding machines, composite panel bonding & textile bonding and other solutions, PUR hot melt adhesive has good seasonal resistance: due to its irreversible characteristics after bonding, it will not be affected by environmental temperature changes resulting in creep and brittleness. High toughness, strong initial adhesion, strong permeability and adhesive force, the adhesive strength is 40% to 60% higher than other adhesives under the same conditions, reducing the amount of adhesive used.

1. Features of barreled moisture curing reactive polyurethane hot melt adhesive:

Adhesiveness and toughness (elasticity) can be adjusted, with excellent bonding strength, good high and low temperature resistance, water resistance, abrasion resistance, zero chemical corrosion resistance

And aging resistance, suitable for the bonding of plastics and metals, widely used in woodworking, automobiles, textiles, electromechanical, electronic equipment and other economic fields.

2. Polyurethane hot melt adhesive type

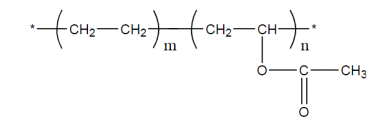

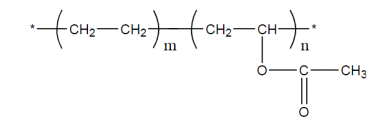

5 gallon moisture curing reactive polyurethane hot melt adhesive (one-component moisture curing polyurethane adhesive), which is one of the types of polyurethane hot melt adhesive. According to the chemical properties, there are two types of polyurethane hot melt adhesives: one is thermoplastic polyurethane hot melt adhesive, and the other is reactive polyurethane hot melt adhesive. Thermoplastic polyurethane hot melt adhesive, also known as hot melt polyurethane hot melt adhesive, is liquefied by heating and solidified by cooling.

Reactive polyurethane hot-melt adhesives are divided into two types: moisture-curing type and closed type. After heating and liquefaction, they are cross-linked and solidified by cooling and moisture reaction. The PUR hot melt introduced today

Adhesive refers to moisture-curing polyurethane hot melt adhesive.

3. Barrel moisture-curing reactive polyhydrogen ester hot-melt adhesive has strong adhesion and high initial adhesion

Since -N CO in the molecular chain of the polyurethane adhesive can react with a variety of active hydrogen-containing functional groups to form interfacial chemical bonds, it is effective for a variety of materials.

Extremely strong adhesive properties. Not only can it bond porous materials, such as foam plastics, ceramics, wood, fabrics, etc., it can also bond a variety of metals, inorganic materials, plastics, etc.

It is an adhesive with a wide range of applications, such as materials, rubber and leather.

4. Outstanding low temperature resistance performance of barreled moisture curing reactive polyurethane hot melt adhesive

At extremely low temperatures, general polymer materials are transformed into glass and become brittle, while polyurethane adhesives can still maintain high peeling properties even below -250°C

Strength, while its shear strength increases significantly with the decrease of temperature.

Purking polyurethane drum PUR packaging: 5 gallon aluminum foil bag (drum), 55 gallon aluminum foil bag (drum), 5kg aluminum foil bag.

PUR hot melt adhesive sizing method

It can be used on special reactive PUR hot melt adhesive machine equipment, with various operation methods.

The above are professional [PUR hot melt adhesive] manufacturers, strength factories, and Purking Adhesive Industry. PUR structural glue can be adjusted appropriately according to customer requirements, and samples are provided free of charge.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик